OHBP Software

OHBP Software

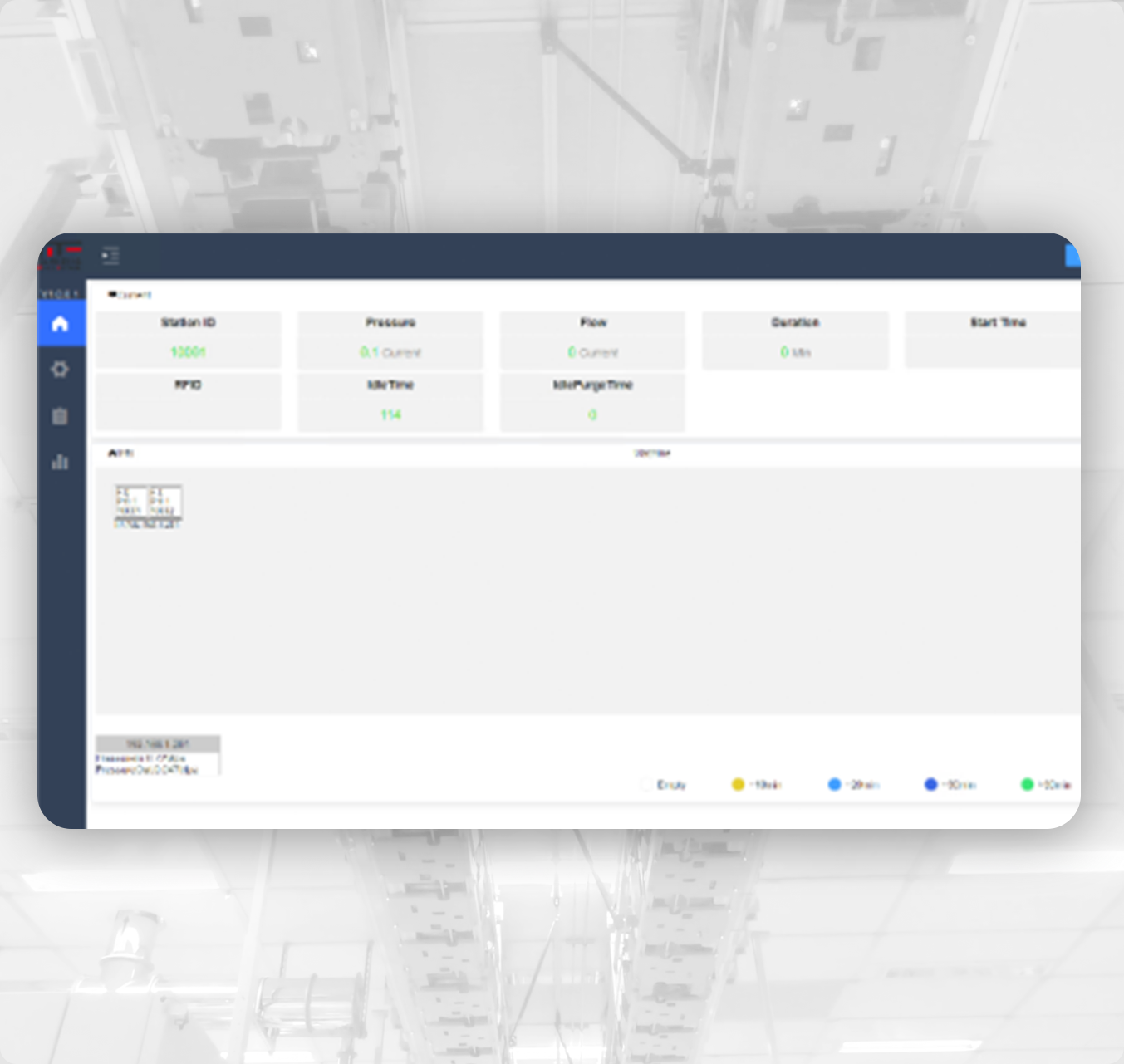

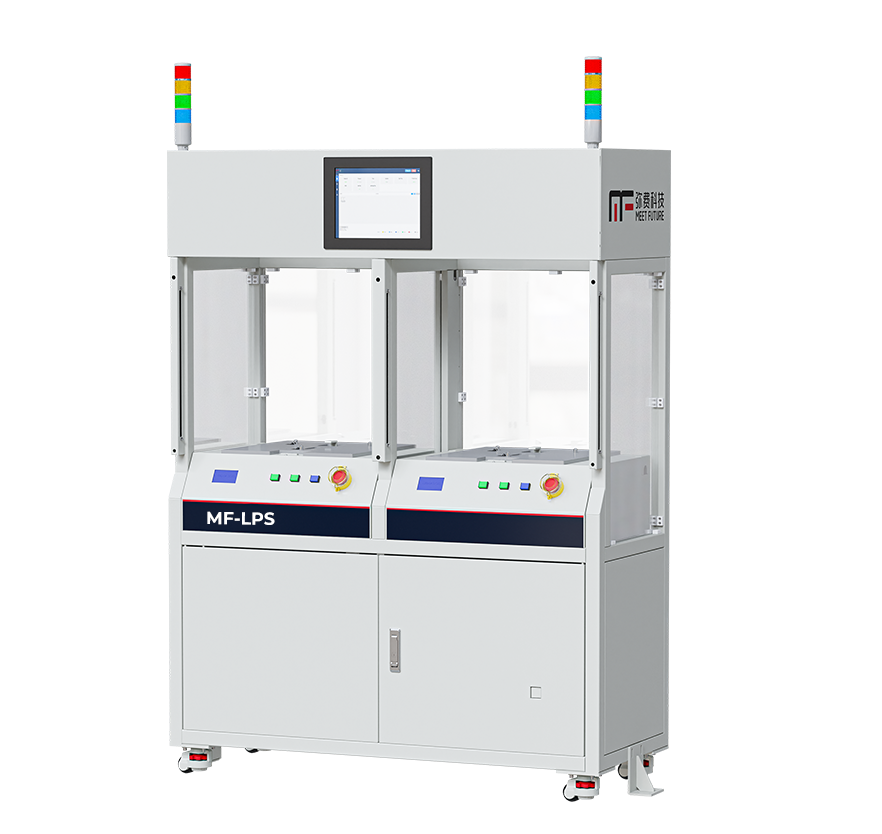

The OHBP control system cleans and purges the ports of the entire bay, offering two modes: continuous purge and inductive purge. It can be equipped with RFID sensors and temperature/humidity sensors, recording the number of Foup placements and tracking temperature/humidity changes throughout the purge process. In case of abnormal RFID readings or substandard temperature/humidity, it provides real-time alarm functionality;

The Web UI interface allows for manual adjustment of the proportional valve, real-time control of airflow, adjustment of temperature, humidity, flow, and pressure monitoring ranges, and manual control of the solenoid valve's switch.

Feature Highlights:

▪ Multi-disk real-time monitoring, ensuring stability and reliability.

▪ With the MF FabScope system, it can quickly pinpoint the location of any abnormal disk status.

▪ Recipe management is supported.

The Web UI interface allows for manual adjustment of the proportional valve, real-time control of airflow, adjustment of temperature, humidity, flow, and pressure monitoring ranges, and manual control of the solenoid valve's switch.

Feature Highlights:

▪ Multi-disk real-time monitoring, ensuring stability and reliability.

▪ With the MF FabScope system, it can quickly pinpoint the location of any abnormal disk status.

▪ Recipe management is supported.

BACK

BACK